Blogs

Our latest blogs

- Geothermal Energy

- February 5, 2026

Last Thursday marked a special milestone for our organization. During a meeting organized by EBN, our colleagues Joël Bruins and Koen Peters had the honor of receiving a prestigious award on behalf of the team.

Within the framework of the SCAN Drilling Campaign program—a research initiative exploring the potential of geothermal energy in the Netherlands—we were recognized as Best Supplier Well Testing Category . This acknowledgment highlights the quality, expertise, and dedication we bring to complex geothermal projects.

We are incredibly proud of this achievement. It is a meaningful recognition of our contribution to , and it reinforces our commitment to the energy transition.

We would like to sincerely thank all colleagues who contributed to this project, as well as our partners and fellow companies involved in the collaboration. This success is truly a team effort.

- General, Geothermal Energy

- February 2, 2026

In just a few weeks, on 26 & 27 February, we will be attending GeoTHERM Expo & Congress in Offenburg (Germany), Europe’s largest trade fair for geothermal energy.

You can find us at booth #330 in the Baden-Arena (Dutch Pavilion).

GeoTHERM brings together professionals from across Europe to exchange knowledge, discover innovations, and shape the future of geothermal energy. We’ll be there to show how we support geothermal projects throughout Europe.

Are you active in the geothermal sector and interested in exploring potential collaboration? We’d love to connect, exchange ideas, and discuss opportunities for your projects.

Will we meet there?

We look forward to seeing you at GeoTHERM!

- Well Testing

- November 19, 2025

We are proud to show our mobile well test set-up in action on location in Belgium, where it was recently used for our client Smape.

This marks an important moment for us: it is the very first time that this fully mobile installation—designed for maximum efficiency—has been put into operational use. A wonderful milestone for our engineers and field teams.

During this assignment, we carried out a coil tubing cleanout campaign in collaboration with Smapé at location Fluxus.

Advantages of our fully mobile well test unit:

✅ Fast Rig-Up/Rig-Down

Minimize the time required for set-up and dismantling. Less downtime means faster turnaround times and smoother project execution — ideal for moving projects forward.

✅ Compact Footprint

Our mobile setup is designed with logistical convenience and limited environmental impact in mind. Perfect for remote or hard-to-reach locations.

✅ Fully Self-Sufficient

Thanks to advanced well testing technology, the system operates completely autonomously. Plug-and-play simplicity, even in the most challenging conditions.

✅ Maximum Efficiency

With seamless integration and rapid deployment, the unit delivers top operational performance. Do more in less time.

✅ Cost-Efficient

Time savings, compact logistics, and low setup costs deliver immediate measurable benefits. Efficiency without compromising on quality or reliability.

Would you like to know more about our mobile testing solutions or discuss what we can do for your project? Feel free to contact us!

- Well Testing, Geothermal Energy, Oil & Gas

- October 15, 2025

When performing a , sampling is also an important part of gaining insight into the well’s performance.

During the clean-up period and flow after flow test our technicians are taking readings & samples and analyze same as per client program, such as;

✅ BS&W’s (basic, sediment of water) Ph, chlorides, sand particles

✅ Sampling H2o & Oil (condensate) taken Sg (specific gravity) pH, chlorides & temperatures

✅ Gas Sg taken on Co2 & H2s & benzene

During this stage Bakker Flow Services can then analyze if a specific well is cleaning up as by criteria.

After the flow after flow test, we can then hand over the well to our client with all relevant information they need in their further stage.

- Rental, Mobile Sound Wall

- September 3, 2025

Looking for an effective noise protection solution for your project? In Germany, we recently installed 340 meters of our modular sound barrier. In the video below, you can see how our mobile soundwall system is assembled on-site.

Thanks to our acoustic solution, residents nearby are not disturbed by ongoing construction work behind the mobile soundwall. With up to 20 dB noise reduction, our noise barrier ensures a quieter and more comfortable environment.

Benefits of our modular soundwall system

✅ Noise reduction: Up to 20 dB (A) for reliable and effective noise control.

✅ Impressive height: Standing 10 meters tall for maximum coverage.

✅ Wind resistance: Resistant to Wind Force 12.

✅ Modular flexibility: A fully adaptable system for different project types and environments.

Our mobile noise barriers are the ideal choice for any situation where the environment needs to be shielded from noise pollution, such as in energy production, construction projects and industrial sites where noise protection is essential.

Looking for the best acoustic protection solution for your project? Our specialists are ready to advise you on the ideal soundwall system for your specific needs.

- Geothermal Energy

- July 16, 2025

We proudly look back on a successful geothermal project, which involved a cleanout operation for one of our valued customers, EBN.

As part of the SCAN team (Seismische Campagne Aardwarmte Nederland), we were involved in a geothermal testing of a well in the Netherlands.

SCAN is a national program made possible by the Ministry of Climate Policy and Green Growth and executed by EBN and TNO , aimed at mapping the Dutch subsurface to accelerate geothermal energy development — a crucial step towards a more sustainable future.

Are you working on geothermal energy? Our team is ready to support your project with customized solutions and effective services.

- General

- June 25, 2025

It’s remarkable how quickly time flies. Just three months ago, we proudly unveiled a new chapter in our story — a new name and a new logo.

This transformation was the culmination of months of strategic reflection, creative exploration, and careful planning. The reveal wasn’t just about a fresh visual identity — it was about aligning who we are today and where we’re headed.

The launch event was filled with excitement, anticipation, and pride. It was a true celebration of our journey, our team, and the vision we share for the future. And while we experienced it in real time, we also made sure to capture it — so that the moment could live on.

Introducing Our Rebranding Launch Aftermovie

We’ve created a short film that captures the spirit of that unforgettable day. From the first reactions to the shared celebrations, the aftermovie reflects the energy and enthusiasm that defined the launch.

Watch the reveal film here and relive the beginning of our next chapter

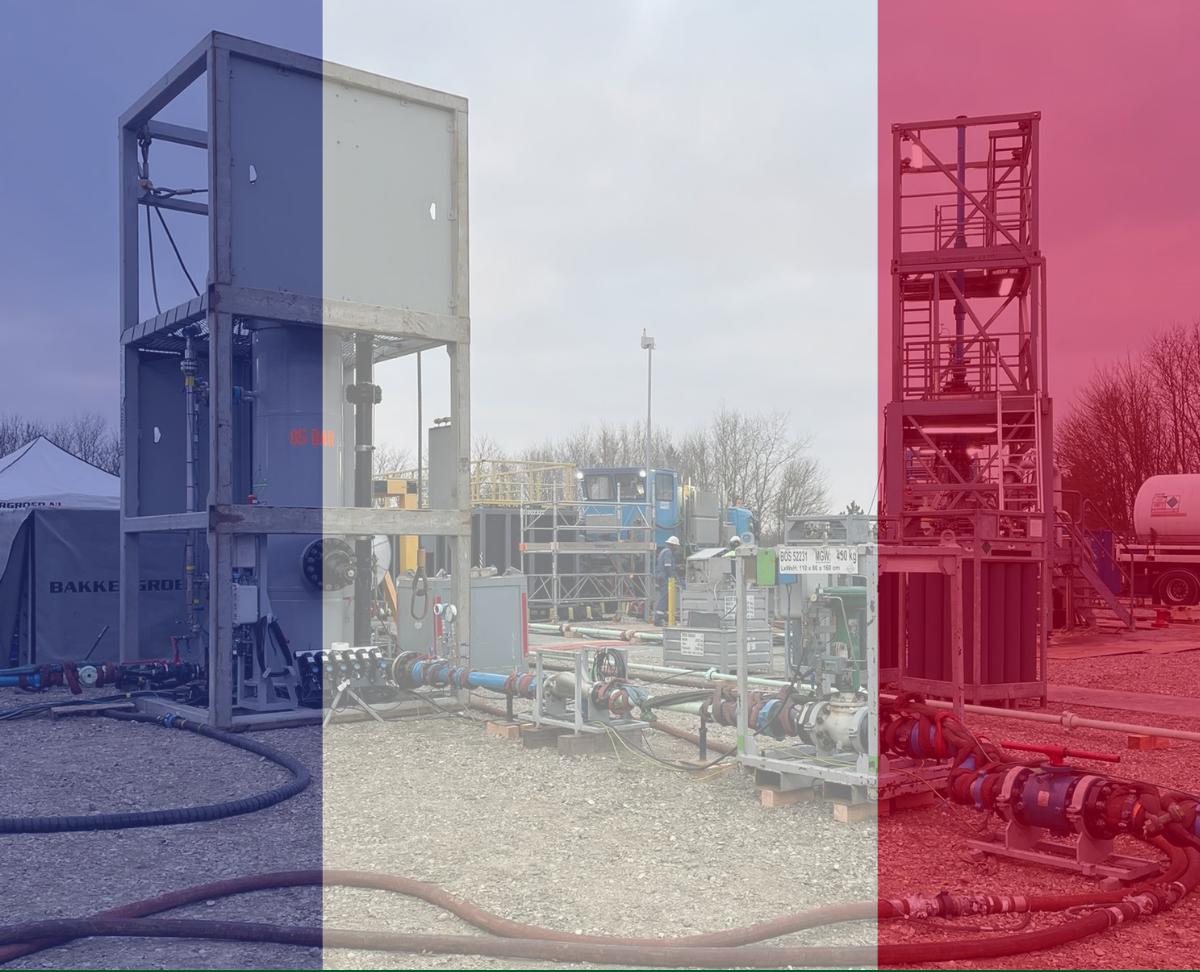

- Oil & Gas, Well Testing

- May 21, 2025

We are proud to announce that Bakker Flow Services has been awarded a significant contract in the French oil & gas sector. This achievement represents an important milestone in our international growth strategy and further strengthens our position within the European energy market.

It reflects the hard work, dedication, and vision of our entire team. We are sincerely grateful to our new client for their trust and look forward to building a successful an long-lasting collaboration.

At Bakker Flow Services, we are equipped for solutions. By continuously investing in innovation, quality, and service, we aim to meet the challenges of tomorrow.

“As Sales & Operations Manager, I see this as the start of a new and exciting chapter. I’m incredibly thankful for this opportunity, proud of what we’ve achieved, and confident in the road ahead.” – Eric Geitz

- Geothermal Energy, Oil & Gas, Well Testing

- April 22, 2025

Take your well testing operations to the next level with our innovative, fully mobile well test setup. Engineered for maximum efficiency, significant cost savings, and effortless deployment, our cutting-edge setup provides it all.

Whether you’re looking for flexibility, speed, or reliability, our mobile well test setup delivers it all – empowering you to operate faster, smarter, and more effectively than ever before.

Why choose our mobile well test setup?

- Effective mobilization: Drastically reduce setup and teardown times. Less downtime means faster turnarounds and smoother project execution, so you can stay ahead of schedule.

- Compact footprint: Designed for mobility, our setup offers logistical and transport advantages while minimizing environmental impact – ideal for remote or hard-to-access locations.

- Fully self-sufficient: Our system is completely autonomous, powered by the latest in well testing tech. It’s plug-and-play simplicity for the most demanding environments.

- Peak Efficiency: Experience operational excellence with seamless integration, advances systems, and rapid deployment.

- Cost effective: Time savings, space efficiency and low setup costs mean one thing: real savings. Optimize your budget without sacrificing performance or reliability.

Prepare your operations for tomorrow! Contact us today and discover how this technology can transform your well testing.

- General

- March 26, 2025

One week ago, we unveiled our new identity, but what went into choosing our new name and logo? Today, we’re excited to share the story behind it.

The name “Bakker Flow Services”

Our new name “Bakker Flow Services” better reflects our evolution and aligns with our mission to be the best designer and performer of technical solutions in the energy sector. Our subline is therefore “Equipped For Solutions” and represents all that!

Fun fact: our employees were directly involved in brainstorming and selecting the new name.

From our identity to our new logo “The Flow”

Our logo is a reflection of our identity. It is actually the mole that inspired the logo. This remarkable creature embodies flexibility, effortlessly moving both forward and backward.

Powerfull, despite it’s size, he continuously explores new paths. Native to Europe, the mole also symbolizes our goal-oriented mindset and determination.

Additionally, the flow symbolizes our continuous progress in the energy sector, aligning with our name. Each line represents one of our core pillars – New Energy, Oil& Gas, Industrial, Rental, Maintenance & Inspection.

Together, they represent our fresh new look, and we hope it resonates with you as much as it does with us.

- General

- March 20, 2025

After months of hard work and dedication, we are thrilled to introduce our new brand identity.

Why the change?

This isn’t just a rebrand – it’s a true reflection of who we are today and where we are headed. Our previous brand no longer fully represents the direction we’ve taken as a company. While we have deep roots in the oil and gas industry, we have increasingly expanded into the new energy sector, which has become a key part of our business.

Our new name and branding better reflects this evolution and align with our mission to be the best designer and performer of technical solutions in the energy sector.

What doesn’t change?

While we’re proud of our new look, we want to reassure you that our core values remain unchanged. At Bakker Flow Services, we are still deeply committed to the things that matter most to you:

- Reliability: We keep our promises and are transparent about our actions.

- Safety: We only work if we can do it safely.

- Quality: We strive for the highest quality both internally and externally.

- Sustainability: We strive for the smallest possible footprint in everything we do.

- Flexibility: Because we’re equipped for solutions.

What’s next?

In the coming weeks, we’ll be sharing the inspiration and thought process behind our new name and logo, so you can learn more about how they reflect our vision and mission.

Welcome to Bakker Flow Services!

- General

- January 15, 2025

We are excited to announce an important change in our leadership. As of this year, Jasper Stroeve has stepped into the role of Managing Director, taking over from Frans Hagel, who has successfully led the company over the past years.

Jasper has had an impressive journey within our company, starting as an intern and progressing through various roles to become a member of our management team. With his extensive experience and deep understanding of our company and the industry, we are confident that he is the right person to drive Bakker Flow Services forward.

A Smooth Transition

Frans Hagel will remain involved in the company as a co-owner of Bakker Groep. Under his leadership, Bakker Flow Services has experienced significant growth, and we are grateful for the vision and dedication he has brought to the company.

The Future

As we enter this new chapter, we remain committed to the core values you have come to expect from us—reliability, safety, quality, sustainability, and flexibility. We are also steadfast in our mission to be the best designer and performer of any technical solution in the energy business.

We are excited about the future and look forward to sharing more updates with you in the coming months, as exciting changes are underway. We wish Jasper all the best in his new role and look forward to the continued growth of our company.

- Rental, Mobile Sound Wall

- December 12, 2024

When working on site, you want to minimize noise and sight disturbance to nearby residents. This can be done by using our mobile sound wall. However, we are seeing an increase in the use of containers at locations where noise reduction is essential. Both solutions are used to reduce noise pollution for nearby residents, but each has its own advantages and disadvantages. Containers may be cheaper but do they offer the same benefits as the sound wall?

A good time for us to compare our temporary noise barrier with the use of these containers to see what is best to use, considering noise reduction, safety, durability, possibilities for adaptation and of course the aesthetic aspect for the environment. Why choose our temporary noise barrier instead of separate containers?

Specially designed for noise reduction up to 20 dB (AQ)

Unlike containers, our mobile soundwall is specifically designed to protect the environment from noise pollution up to 20dB(AQ). It is precisely calculated to achieve the best noise reduction and manufactured from materials with excellent acoustic properties.

It is constructed from HEA140 steel sheet piling profiles that are 0.63mm thick plus a 0.63mm thick perforated steel plate, padded with 50mm mineral wool insulation between the sheets. The noise reduction of our sound wall has been extensively tested and recorded in a written report by TNO, a leading research institute in the Netherlands. Since you want to keep the inconvenience to a minimum for nearby residents, this report provides assurance, that the sound wall contributes to minimizing noise pollution for the environment. The soundproofing ability of steal stacked containers depends on several factors such as the height of the stack of containers but also the density. If there are gaps between the containers, sound can penetrate through them.

Safety

Stay safe with a well-lit worksite and resistance to wind forces up to 12 Bft.

Flexibility and customization

- Dismountable and reusable: As it is a modular system, the mobilee sound wall can be easily adapted to your preferences and site requirements, creating an optimal sound barrier.

- Space-saving: Unlike containers, which take up a lot of space, the sound wall offers a more compact and efficient solution.

- Customization: Depending on your specific needs, we have a choice between a manual or electric overhead door as wide as 5 meters. In addition, we have doors for emergency exits and special cable ducts. Furthermore, we can provide you with matching lighting. Our hanging LED lighting systems are specially designed for use on our sound wall.

Durability and environmental friendliness

Our mobile sound wall is designed for long-term use, as it is made of durable materials and resistant to weathering. This makes it a sustainable choice. In general, containers are more susceptible to damage and can therefore rust faster.

Aesthetics and neighborhood friendliness

The walls have a tighter and more professional appearance than containers, which creates a neater impression. This contributes to a positive relationship with neighborhood residents and can reduce complaints.

In short, both can be used against noise. Although stacked containers can be a quick and relatively inexpensive solution to temporary noise problems, in most cases the mobile sound wall is a much more effective choice. They offer better noise reduction and flexibility, are more durable and are more aesthetically pleasing.

For more details about our mobile sound wall, check out our dedicated page here, or feel free to contact us with any questions!

- Geothermal Energy, Oil & Gas, Well Testing

- September 24, 2024

Prepare to experience the next level of well testing with our mobile well testing set. This innovative solution, arriving soon, will deliver unmatched efficiency, cost savings, and ease of use, empowering you to maximize the potential of your operations.

Key advantages of our Mobile Well Testing Set include:

- Shorter rig-up/down time: our mobile well test set significantly reduces rig-up and rig-down time. This means less downtime, faster turnaround, and smoother project execution, ensuring you stay ahead of schedule.

- Smaller footprint: with its compact footprint, our mobile set offers logistical and transportation advantages while minimizing environmental impact. Ideal for operations in remote or hard-to-reach locations, it provides the flexibility you need.

- Innovative and self-sufficient: designed with cutting-edge technology, our mobile well test set is fully self-sufficient. No additional infrastructure is required, simplifying and accelerating your operations. It’s a seamless solution for today’s demanding environments.

- Efficiency at its finest: boost the efficiency of your well testing operations with our mobile set. The seamless integration of advanced systems and rapid deployment capabilities lead to unprecedented operational efficiency, allowing you to achieve more with less.

- Cost-saving: reduced installation and teardown times, a smaller footprint, and enhanced efficiency directly translate to cost savings. Our mobile well test set helps you optimize your budget without compromising on quality and reliability.

- Unique in the market: there’s nothing else like it. Combining innovative technology, self-sufficient systems, and unparalleled efficiency, our mobile well test set is unique in the market, setting a new standard for well testing operations globally.

Be ready for the future of well testing. Contact us today for more information and to be among the first to experience this groundbreaking technology when it becomes available.

- Geothermal Energy, Well Testing

- September 11, 2024

We’re excited to announce the completion of a successful geothermal well test for HVC on both a production and injection well!

The process began with a nitrogen lift (clean-out) of the injection well, ensuring it was fully prepared. From there, we connected to both wells to perform a closed loop test, which went smoothly and efficiently.

This achievement is a result of teamwork and dedication. A big thank you to everyone who contributed to making it happen! We’re looking forward to the next challenge.

Stay tuned for more updates as we continue pushing forward in new energy!

For more details about our geothermal well testing services, check out our dedicated page here, or feel free to contact us with any questions!

- Geothermal Energy, Oil & Gas

- September 5, 2024

We are excited to unveil our newest addition to the equipment lineup — the 10K Cyclonic Wellhead Desander. This cutting-edge desander is engineered to effectively separate sand and other solid particles from the well stream, achieving separation efficiencies of up to 99%. Even at high flow rates, this efficiency is consistently maintained, ensuring your operations run smoothly and efficiently.

Key features of the 10K Cyclonic Wellhead Desander

- High efficiency in separation of solid particles: Our desander excels in separating sand and other solid particles, delivering an impressive separation efficiency of up to 99%. This high level of performance is sustained even under high flow conditions, ensuring your well stream remains free of unwanted solids, thereby protecting downstream equipment and maintaining optimal flow.

- Dual vessel set-up: To guarantee uninterrupted operations, the 10K Cyclonic Wellhead Desander is equipped with a dual vessel set-up. This configuration allows for continuous operation, as one vessel can be in use while the other is being serviced, ensuring there is no downtime in your processes.

- Minimum back pressure: Designed to handle high flow rates with minimum back pressure, our desander keeps your system functioning at its best. The low back pressure design helps maintain the integrity of the well stream flow, reducing the risk of pressure-related issues and optimizing overall system performance.

- Representative sand sampling: Understanding sand production rates is crucial for effective well management. The 10K Cyclonic Wellhead Desander offers the ability to take representative samples of sand, enabling accurate estimation of sand production rates. This feature allows for better monitoring and management of your well, leading to more informed decision-making.

The perfect solution for your project

The 10K Cyclonic Wellhead Desander is ideal for industries dealing with sand and solids in their well flow. Its robust design and innovative technology ensure reliable and efficient performance, maximizing your operational efficiency and productivity. By investing in this advanced desander, you are equipping your operations with a solution that delivers exceptional results, helping you achieve your operational goals.

Curious if it’s the ideal solution for your project? Contact us for more details.